|

|

|

|

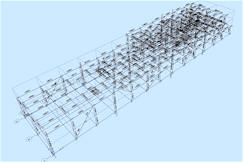

Structural Engineering and Design in California

|

We

perform a variety of structural engineering

services for all types of

buildings including wood, steel,

concrete, masonry or tilt-up buildings,

new homes, renovations, extensions,

cottages, studios, guest houses, decks

and patios.

Our

structural design services are including

foundation plans with footing,

structural framing layouts with decking,

joist and trusses, roof trusses, ceiling

joists, and joist details, blown up

connection details and quantity

estimations with measurement sheets. |

|

|

|

Please

call

![Peyman Group [714] 496-8466 Mechanical Consultant Engineering in Orange County, CA](images/image_87.jpg) Peyman

Group NOW to have preliminary discussion about your Structural

engineering and design project and

immediate assistance by our experts. Peyman

Group NOW to have preliminary discussion about your Structural

engineering and design project and

immediate assistance by our experts. |

|

Some sample guidelines for

structural plans followed by

![Peyman Group [714] 496-8466 Mechanical Consultant Engineering in Orange County, CA](images/image_87.jpg) Peyman Group

designers are: Peyman Group

designers are:

CONCRETE AND MASONRY STRUCTURES

Use a minimum concrete ultimate compressive

strength of 3000 psi at 28 days. Use a minimum concrete ultimate compressive

strength of 3000 psi at 28 days.

Specify size of aggregate and slump. Use

1-inch or ¾-inch minimum aggregate size, with

smaller sizes only in very special cases. Specify size of aggregate and slump. Use

1-inch or ¾-inch minimum aggregate size, with

smaller sizes only in very special cases.

Avoid thin sections or projections that may

crack off when forms are removed. Chamfer column

corners, exposed corners and edges. Avoid thin sections or projections that may

crack off when forms are removed. Chamfer column

corners, exposed corners and edges.

Provide typical construction joint locations

for concrete beams, joists and slabs. Provide typical construction joint locations

for concrete beams, joists and slabs.

Provide expansion joints, control joints and

seismic-movement joints as required by the

design, indicate their locations and details on

drawings and coordinate with architectural

enclosures and finishes. Provide expansion joints, control joints and

seismic-movement joints as required by the

design, indicate their locations and details on

drawings and coordinate with architectural

enclosures and finishes.

|

Maintain a full depth of slab under

depressions for ceramic tile, electric ducts or

other construction. Maintain a full depth of slab under

depressions for ceramic tile, electric ducts or

other construction.

Provide a typical column drawing indicating

bar maximum slopes, locations of splices and reglets for shear-wall reinforcing. Provide a typical column drawing indicating

bar maximum slopes, locations of splices and reglets for shear-wall reinforcing.

When setting a rail post use non-shrink grout

or equivalent (“Por-Rok” but not sulfur).

Provide a #4 bar on each side of post in

concrete. When setting a rail post use non-shrink grout

or equivalent (“Por-Rok” but not sulfur).

Provide a #4 bar on each side of post in

concrete.

If wood or steel studs are used in concrete

buildings, indicate clear relationship between

“face of concrete” and “face of studs”. If wood or steel studs are used in concrete

buildings, indicate clear relationship between

“face of concrete” and “face of studs”.

In masonry walls, base dimensions on modular

size of the unit. In masonry walls, base dimensions on modular

size of the unit.

In concrete masonry walls, fill all cells

except on free-standing site walls retaining no

earth. Avoid bars larger than Number 8. In concrete masonry walls, fill all cells

except on free-standing site walls retaining no

earth. Avoid bars larger than Number 8.

Clearly show the minimum

concrete cover required for the intended fire

protection rating. Clearly show the minimum

concrete cover required for the intended fire

protection rating. |

|

|

|

STEEL STRUCTURES

Provide top-of-steel elevations at each column

and change of level on structural

drawings for ease of reference by steel

detailers and erectors. Provide top-of-steel elevations at each column

and change of level on structural

drawings for ease of reference by steel

detailers and erectors.

For exterior steel work specify sections with

a thickness of ¼” or greater. For exterior steel work specify sections with

a thickness of ¼” or greater.

Indicate required camber on all tapered steel

girders and steel trusses. Indicate required camber on all tapered steel

girders and steel trusses.

Keep steel floor beams to L/D equal to or less

than 24. Keep steel floor beams to L/D equal to or less

than 24.

|

Specify cost effective size, length and type

of welds. Use standard weld symbols and consider

fillet welds where adequate. Specify cost effective size, length and type

of welds. Use standard weld symbols and consider

fillet welds where adequate.

Make groove welds "full penetration" on

structural welds such as tapered girder flanges. Make groove welds "full penetration" on

structural welds such as tapered girder flanges.

On welded assemblies to

be hot-dip galvanized, avoid shop

welding large areas, such as stair

platforms, to prevent warping in

galvanizing bath. Field weld and retouch

galvanizing, or use cadmium plated

counter-sunk flat head machine screws

for field assembly. On welded assemblies to

be hot-dip galvanized, avoid shop

welding large areas, such as stair

platforms, to prevent warping in

galvanizing bath. Field weld and retouch

galvanizing, or use cadmium plated

counter-sunk flat head machine screws

for field assembly.

Provide means of leveling for base plates,

such as double nuts on anchor bolts. Provide means of leveling for base plates,

such as double nuts on anchor bolts.

|

|

Provide complete roof

framing plans showing walls. Clearly

indicate corner framing and slope of

roof. Provide complete roof

framing plans showing walls. Clearly

indicate corner framing and slope of

roof.

Use nominal 6" wide

studs for walls with the exception of

non-bearing walls with no piping. Use nominal 6" wide

studs for walls with the exception of

non-bearing walls with no piping.

Clearly indicate

connection of vertical shear elements to

diaphragms. Be sure these shear elements

do not produce a high concentration of

stress over a small length. Clearly indicate

connection of vertical shear elements to

diaphragms. Be sure these shear elements

do not produce a high concentration of

stress over a small length.

Use minimum 1/2" thick

plywood for roof sheathing. Indicate

stagger of panels required for

horizontal diaphragms. Use minimum 1/2" thick

plywood for roof sheathing. Indicate

stagger of panels required for

horizontal diaphragms. |

|

|

|

|

|

|

|

|

|

Professional Engineering

Design Services |

More

Professional Services

|

|

|

|

|